TTEngineering has proven abilities in manufacturing different types of industrial automation systems, characterized by high customization levels. We can manufacture highly automated solutions in different industrial sectors thanks to our long-term experience in process engineering.

For example we have designed and created highly productive machines and systems for the manufacturing of pencils and disposable syringe needles for the medical sector, but also locks and micro-switches, systems for dosing and coating paper or wood with adhesive materials; all these applications have been duly integrated by TTE with packaging systems.

The medical sector: the origin of our expertise

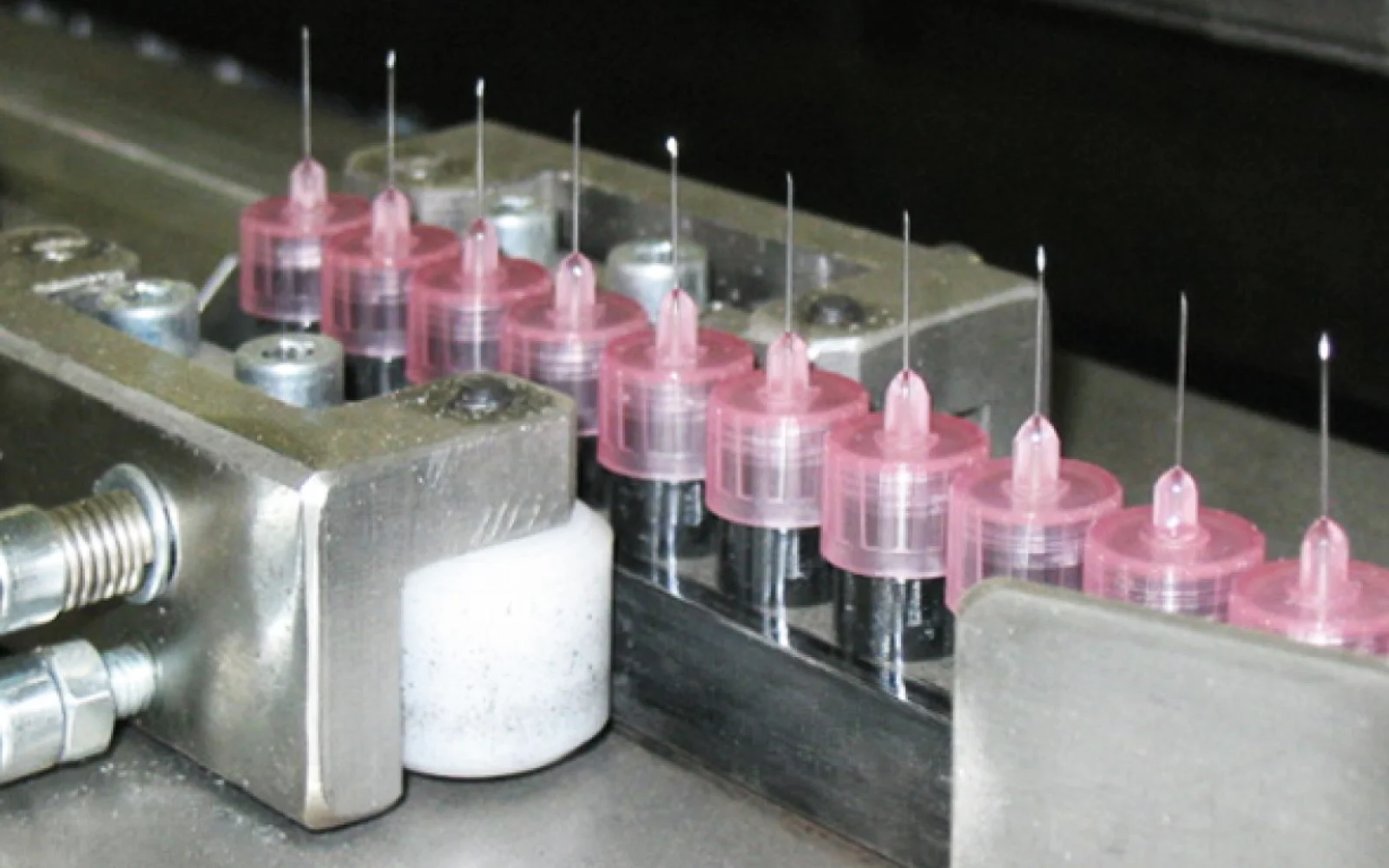

TTEngineering’s first automation lines were developped for the assembly and packaging of disposable insulin needle components.

We are talking about extremely productive systems with high process automation, ensuring outstanding standards in terms of production and quality efficiency.

There are also some examples of single and double lines, which allow the production of 12 or 24 pieces per second. These lines, working obviously in clean rooms, are characterized by two parts: the first one manages semi-finished products placed on the rack, while the second one receives the rack with finished syringes and splits it. The following step of the process involves needles closing, labelling, quality checks up to packaging of finished products.

Highly customized systems

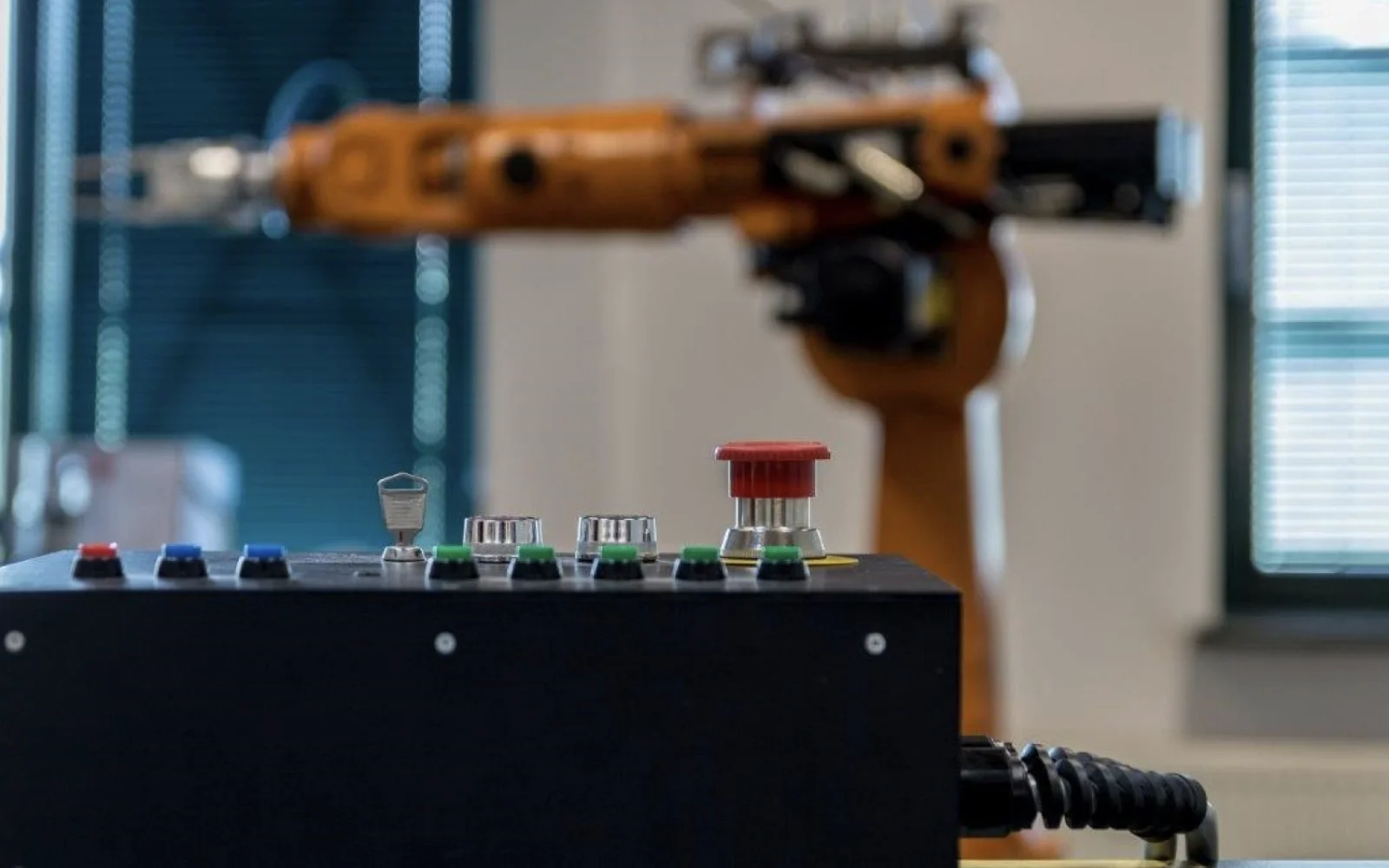

These plants can be operated both electrically or pneumatically and may be integrated with rotating tables, asynchronous systems, as well as automatic workpiece loading systems (vibrating screens). Each plant is provided with product check and inspection systems. A wide variety of assembly technologies is available, from floating pallets, indexing tables, to continuous systems with anthropomorphic robots, SCARA robots or pick-and-place systems.