Thanks to its abilities in the automation field, TTEngineering offers also highly flexible automatic pipe production lines, carrying out bending and welding in one shot.

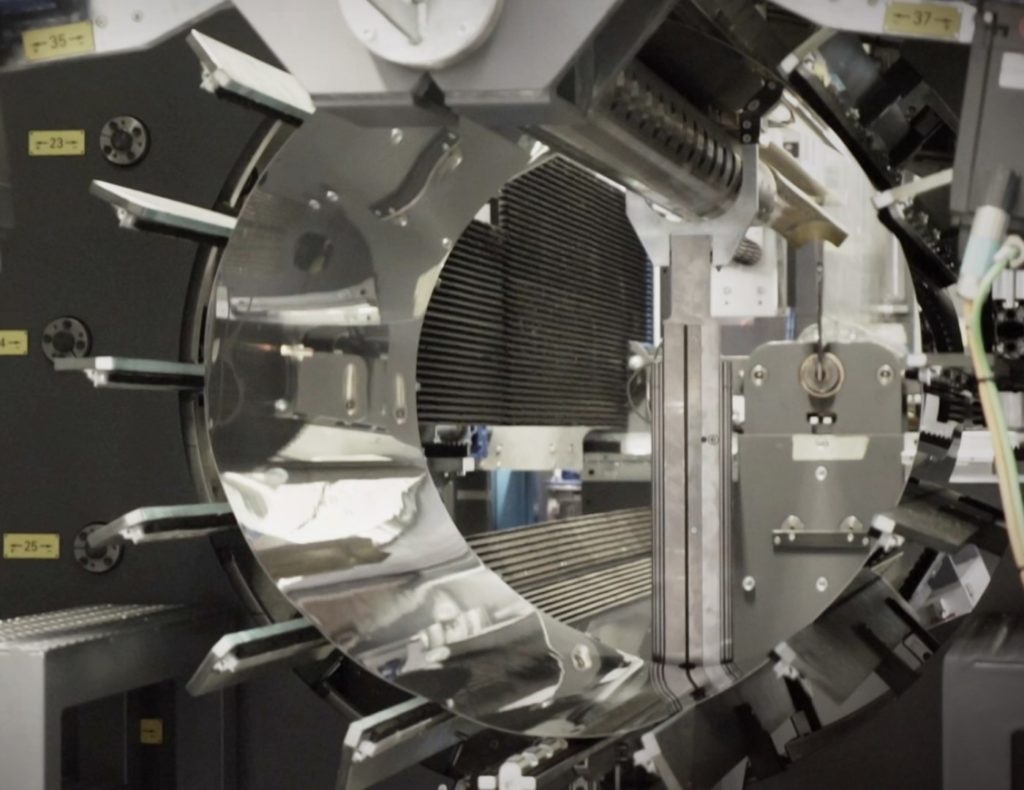

The standard layout consits of one or two destacker tables with pre-cut sheets, a roll-bending system with FlexFormer®, an automated transport system of ferrules to the welding station, a welding unit (multi-process as well) and a finished pipes unloading system.

Automation and quality

In the most recent and flexible Full Automatic version process parameters setup is carried out completely automatically as diameters change.

The distinctive feature of these automatic lines is represented by the pipe bending and welding technology. The welding unit always works with the pipe blocked in a specific position, while the torch moves along the welding joint (a multi-stroke movement is applicable as well). This application guarantees excellent welded joints; on top of that the process can be repeated with high quality and reliability standards.

TTE also offers certified verification systems of the welding process: thanks to real time procedures it is possible to obtain reports (data register and parameters traceability) with specific reference to the single article and the related process. Integration with the client’s management software is provided together with all the data exchanged with the plant’s main control.

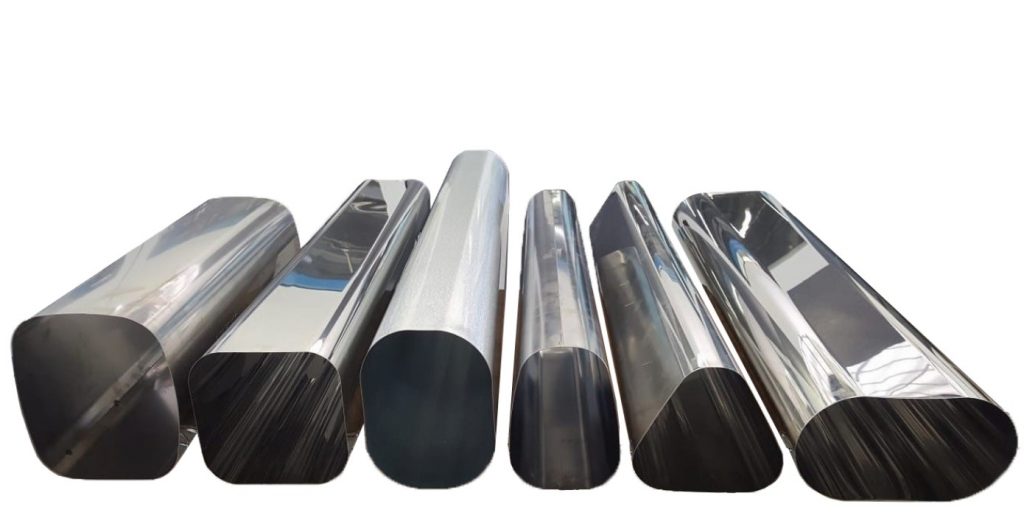

The extreme flexibility of this solution gives the client the guarantee to be able to produce multi-shape pipes (round, oval, elliptical, rectangular), working on a wide range of diameters and thicknesses, by easily selecting the in-memory receipes without any pause, that is without changing format and without any downtime.

TTEngineering is an engineering company, whose main activity is the production of automation systems for sheet metal processing for the production of heating pipes, ventilation pipes, chimneys and for the automotive industry.

Vicolo Cirimido, 7

22074 LOMAZZO (COMO)

Vicolo Novaia, 10

22074 LOMAZZO (COMO)